As we have moved into Halls 8.0 & 8.1, there are new rigging restrictions to consider when designing your stand.

If your stand sits within a no-rig zone, our Customer Succcess team will have reached out to you directly.

Please see the Rigging plans section of this page to see the different plans for the different halls to clarify the different Rigging heights. Below is a floorplan indicating the fixed rigging points and also restrictions for the show.

The service of basic anchoring points (also called rigging) is exclusive to Fira and offered through its official provider. It is prohibited to hang any element directly from the ceiling of the halls and facilities.

Rigging is something we’d like to focus on improving as we move to our new home at Fira Gran Via and we highly encourage you to place your rigging orders as early as possible. The deadline to order rigging is the 29th November 2025 but we encourage you to place orders as soon as possible. After the deadline, rigging will not be possible.

The exhibitors or their appointed stand contractors must request the rigging points according to the load distribution conducted by their qualified technician. Rigging points shall not bear a load exceeding 150kg per point to ensure the structural stability of the ceiling. The load per point must include the truss, structures, safety steel, spotlights, banners, manual chain hoists (approximately 35kg each) or electrical chain hoist (approximately 50kg each). It is not always possible to locate anchoring points in all the exhibition areas of the hall, since there may be restrictions that depend on the hall and the points already in use, as well as the load capacity of the ceiling. In this circumstance there may be a requirement for prior adjustment for the rigging (pre-rigging). This adjustment may entail additional costs that shall be charged to the exhibitor or their appointed stand contractor

The structures must be designed to resist the static and dynamic loads associated with their final design, as well as consider their steps for build-up and breakdown.

Rigging Plans

Below are the links to the different Rigging Plans:

Hall 8.0 Rigging Plans

Hall 8.1 Rigging Plans

Rigging Regulation

Branded rigging is considered an additional sponsorship opportunity and must therefore be booked with the organisers. The fee incurred by the additional sponsorship opportunity is for the advertising rights only. You are responsible for the production of the rigged item and placing your rigging order by the specified deadline.

The minimum distance permitted between anchoring points is 1m.

The maximum hanging weight permitted for rigging elements is 15 kg per m², calculated by the ratio of the total weight of the suspended elements to the hired stand surface.

It is not permitted to raise any truss grid with more than 6 manual chain hoists.

The maximum load weight of a rigging point is 1.50 kN (150 kg). It must include the weight of the lift equipment (motors, hoists, etc.).

The loads transferred to the structure at any point due to lifting elements and that act on the halls cannot exceed the maximum load capacity of the point and its elements.

The materials used must be of a high quality, in a good state, bear the CE (European Conformity) marking and have an up-to-date revision.

The truss structures and materials belonging to the Exhibitors are only permitted if they have the CE (European Conformity) certification and are in excellent working condition.

Exhibitors are not permitted to hang any element from the auxiliary structures installed in the ceiling of the venue.

The elements hanging from the ceiling must maintain the vertical nature of the point.

The maximum recommended distance between the anchoring points that use a truss is 10m for general lighting.

It is prohibited to alter any equipment installed by the official provider, including trusses, wires, shackles, or rope slings.

If your stand is located in 8.1, the maximum rigging height is 7m from the floor to the top of the rigged element. The minimum height is 4m. In some locations, further height restrictions may apply. You must inspect your stands location.

Any rigged elements must be a minimum of 1m from any partition walls with neighbouring stands.

Safety wires must be put in place for electrical motors and manual chain hoists and all hanging equipment and components on a truss (lights, sound equipment and speakers, signs, etc.) must be secured with secondary safety wires/chains and metal flanges.

If your stand is located in 8.0; please read the below carefully:

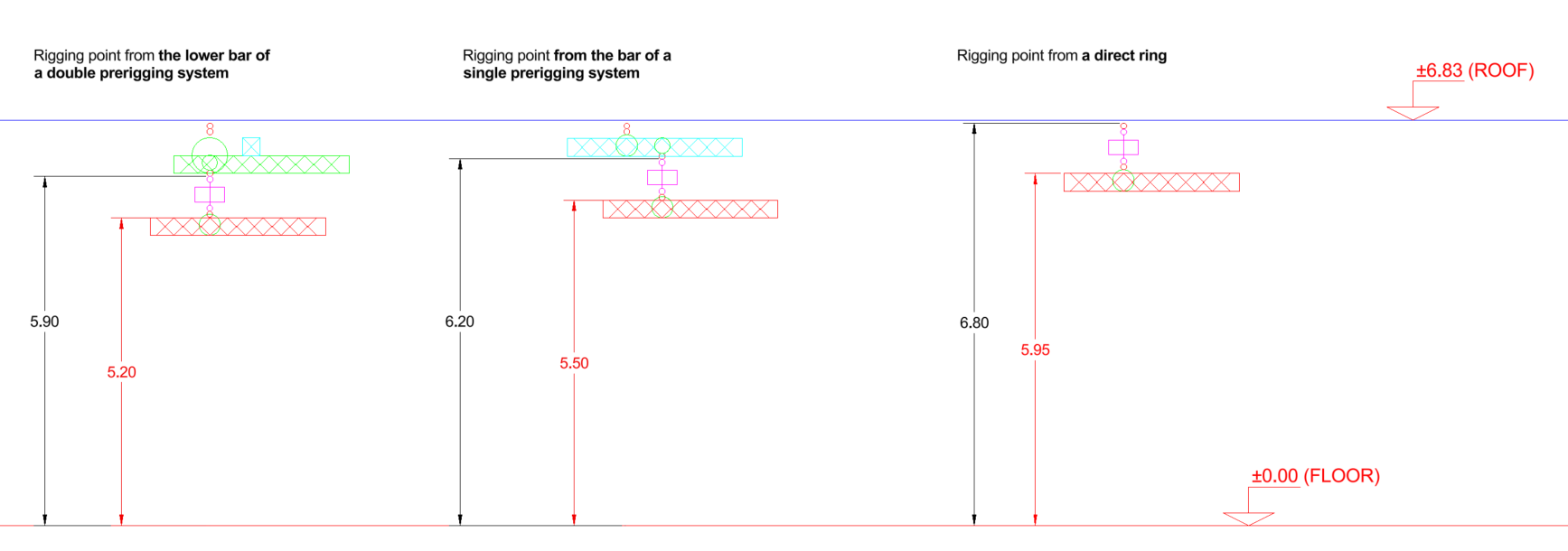

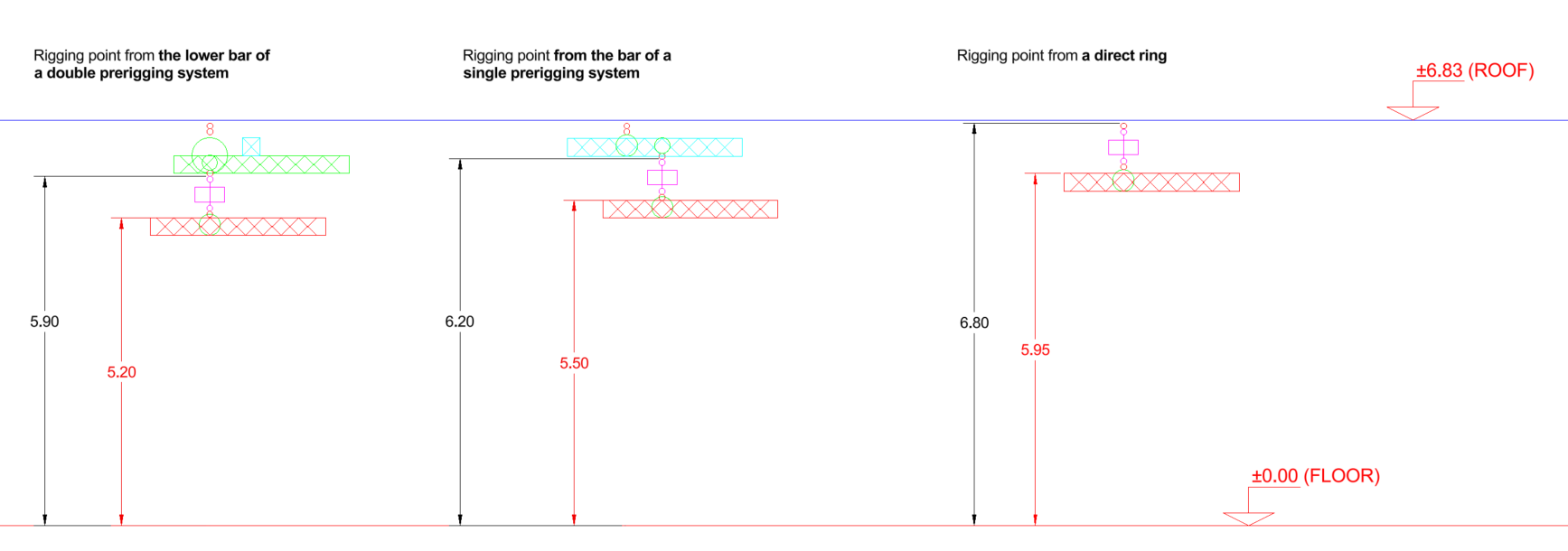

The rigging height (O-ring) is indicated in black, in red, and you can see the final height of top of truss in the case of installing an electrical chain hoist. As shown in the diagram, in the case of two levels of pre-rigging, the top of the truss would be 5.20 m high; in the case of one level of pre-rigging, it would be 5.50 m; and in the case of direct rigging, 5.95 m.

Placing your Rigging Order

To request the rigging service, it is necessary to fill out the form available online via the ServiFira webshop and submit it along with the documentation listed below:

A drawing (in AutoCAD 2010, if possible) indicating the height, the weight supported by the anchoring point and the orientation of the stand in the hall.

The rigging request form (available online at the ServiFira webshop), indicating company information and rigging requirements.

The point type (with or without safety wires, manual chain hoists or electrical motor).

Based on the complexity of the request (number of points, location, simultaneity of requests, etc.), and at the request of Fira, the following must be submitted:

A technical description of the design materials.

Justification of weight calculations of the points.

Quality certificates of the materials.

Justification of the revision of motors, hoists or any other machinery.

A description of the build-up/breakdown procedures to prevent damage to the hall structure or anything which may present a risk to the installations or personnel

The data provided must be submitted with measurements from the International System of Units and in Spanish or English. In the case of detecting some deficiency in the materials or when completing the work, the organisers can stop the operation until the required documentation is submitted or the procedures used are corrected.

Please click here to request rigging.

Complex Rigging

All complex rigging must be checked by the appointed engineer prior to it being lifted. Once approved by the appointed engineer, you will be issued with a 'Permit to raise’.